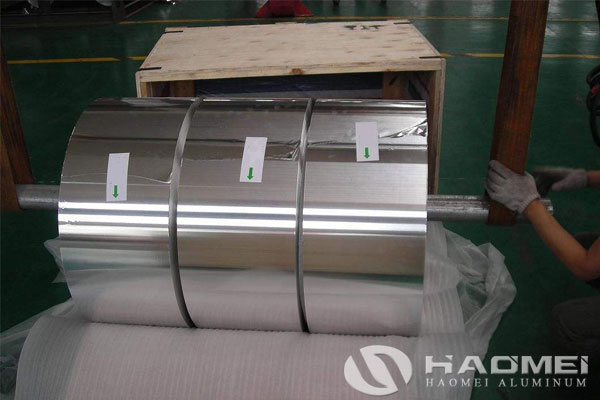

Flexible packaging is a bag-type container or soft tube made of flexible composite packaging materials. The appearance of flexible packaging has greatly improved the mechanization and automation level of the food and beverage industry, and has accelerated the modernization and socialization of people's eating and drinking life. The raw material for processing flexible packaging product is aluminum foil jumbo roll and other materials.

In developed countries, flexible packaging has become one of the main packaging forms for food and beverages, replacing canned and bottled products within a certain range. In recent years, China's flexible packaging market has also developed rapidly. Aluminum foil composite production lines have been introduced, which can be used in different processes such as dry compounding, hot melt compounding and extrusion compounding depending on the use of flexible packaging. Flexible packaging is not only moisture-proof and fresh-keeping, but also can print a variety of patterns and texts, making it an ideal material for modern commercial packaging.

Aluminum-plastic composite tubes are widely used in the packaging of toothpaste, cosmetics and some industrial products because of the excellent barrier properties, strong corrosion resistance and good printability. In 2002, aluminum-plastic composite pipes have completely replaced the toothpaste packaging of traditional aluminum tubes. In addition, the demand for aluminum-plastic composite hoses in the fields of medicine and health care products, cosmetics, condiments, and industrial supplies has also increased to varying degrees.With the improvement of people's living standards, there is still much development space in flexible packaging aluminum foil roll.

live:onlinehcx