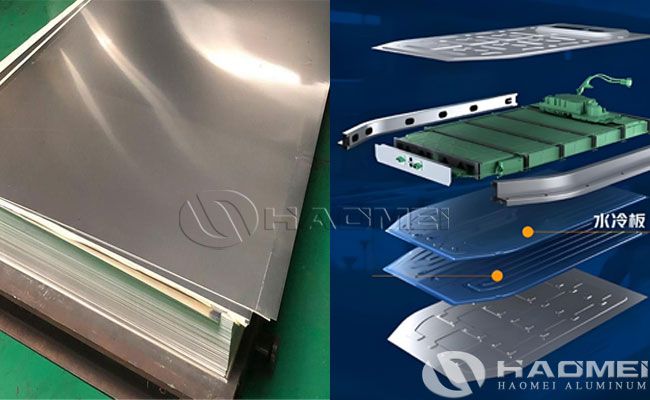

Aluminum sheet double clad 4045/3003/4045 H14 is a composite structural material designed for heat exchangers. Double clad aluminum sheet 4045/3003/4045 H14 is a composite of 3003 aluminum alloy and 4045 aluminum alloy, combining the advantages of the two aluminum alloys. It is often used in fields that require high strength, light weight and efficient heat dissipation (such as new energy vehicle battery thermal management system, radiator, etc.). 3003 and 4045 are used in radiators and water-cooled plates, combining the formability of 3003 and the welding performance of 4045. At the same time, 4045, as a brazing material, may be used in the middle layer or surface layer to help connect other components.

Structural design of aluminum sheet double clad 4045/3003/4045 H14:

A three-layer composite structure is adopted in aluminum brazing sheet, the middle layer is 3003 aluminum-manganese alloy (manganese content 1.0-1.5%), the upper and lower surface layers are 4045 aluminum-silicon alloy (silicon content 4.0-6.0%), and the total thickness is usually between 0.10-0.15mm. This design combines the high corrosion resistance of 3003 (resistant to atmosphere, fresh water and weak acid and alkali environment) with the low melting point (about 600-650℃) and high fluidity of 4045, which is particularly suitable for brazing process.

Heat treatment state of double clad aluminum sheet 4045/3003/4045 H14:

H14 means that the material is partially annealed after cold working hardening, with medium hardness (about 70-90HB) and strength (tensile strength 200-300MPa), while maintaining a certain ductility, which is easy to form and process.

Interface characteristics of double clad 4045/3003/4045 H14 aluminum sheet:

Metallurgical bonding is formed through rolling composite or casting and rolling process, the interface diffusion layer is about 15 microns, and the tensile strength reaches 117.3MPa, which is higher than the pure 3003 matrix, ensuring the strong bonding between the layers.

Typical application areas of aluminum sheet double clad 4045/3003/4045 H14:

1. Automotive thermal management system: radiator fins, water tank baffles, air conditioning evaporators, etc., using the brazing property of 4045 to achieve efficient connection, while the 3003 layer provides long-term corrosion protection.

2. Industrial equipment: chemical pipelines, pressure vessels, combining corrosion resistance and weldability, suitable for liquid or gas medium environment.

3. Special environment: In marine or humid environments containing chloride ions, the corrosion resistance in the plane direction is better than that in the cross-sectional direction, and attention should be paid to the structural design to avoid galvanic corrosion.

Aluminum sheet double clad 4045/3003/4045 H14 is a high-performance composite material that combines the weldability and thermal stability of high-silicon aluminum alloys with the corrosion resistance of aluminum-manganese alloys, and optimizes strength and formability through the H14 temper. It is widely used in the fields of automobiles, electronics, construction, etc., and is especially suitable for scenarios that require corrosion resistance, efficient heat dissipation and welding.

live:onlinehcx