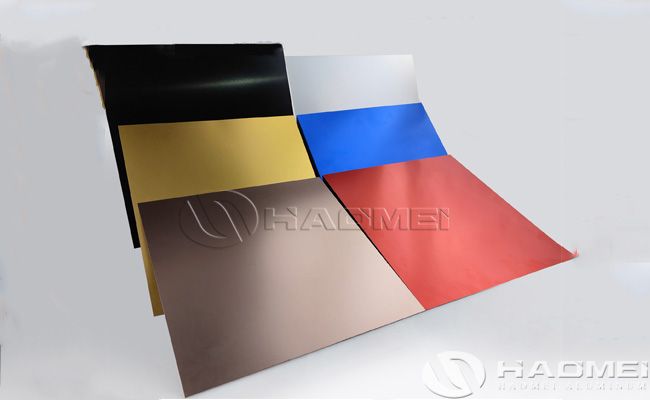

Anodized aluminum sheet manufacturers produce high grade aluminum with anodized aluminium as the main component, and the common colors of anodized aluminum sheets are gold, silver, black, blue, copper and so on. These colors can be applied in different fields and scenes. Haomei anodized aluminum sheets are applied to construction field, can be used in the internal and external walls, ceilings, floors and other parts of the building, to improve the aesthetics and performance of the building, electronic field, decoration field, etc.

Its common specifications are as follows:

Specification size: the regular thickness of anodized aluminum sheet is usually between 0.5-50mm, width between 10-2440mm and length between 500-1219mm. According to different needs, different specifications of anodized aluminum sheet can also be customized.

Appearance quality: high-quality anodized aluminum sheet has a flat and smooth appearance, no obvious scratches, bubbles, delamination and other phenomena, and the color is uniform and consistent.

Performance indicators: the performance indicators of anodized aluminum sheets include density, hardness, bending strength, thermal conductivity, corrosion resistance and so on. These indicators need to meet the requirements of the relevant standards to meet the needs of different areas of application.

The producing process of anodized aluminum sheet manufacturers includes the following steps:

1, Degreasing:

The oil, dust and other substances on the surface of the aluminum sheet are completely removed, usually by chemical cleaning or mechanical cutting.

2, Etching:

The surface of aluminum sheet is etched with acid or alkali solution to remove oxide film and other impurities.

3, Neutralization:

Neutralize the surface of aluminum sheet with neutralizing solution to adjust its acidity and alkalinity in preparation for subsequent anodizing.

4, Anodizing:

Put the aluminum sheet as an anode into the electrolytic solution, and generate a layer of aluminum oxide film by oxidation reaction on the surface of the aluminum sheet after energizing.

5, Coloring:

After anodizing, the aluminum oxide film is dyed or electrolytically colored to make different colors.

6, Sealing:

After dyeing or electrolytic coloring, the aluminum oxide film is sealed to enhance its corrosion resistance and aesthetics.

7, Inspection and Packaging:

Quality inspection of the finished products, packaging after passing to facilitate transportation and storage.

In the whole anodizing process, it is necessary for anodized aluminum sheet manufacturers to strictly control the process parameters, such as current density, electrolyte composition and concentration, temperature, etc., to ensure stable and reliable product quality. At the same time, it is also necessary to pay attention to environmental protection and safe production.

live:onlinehcx