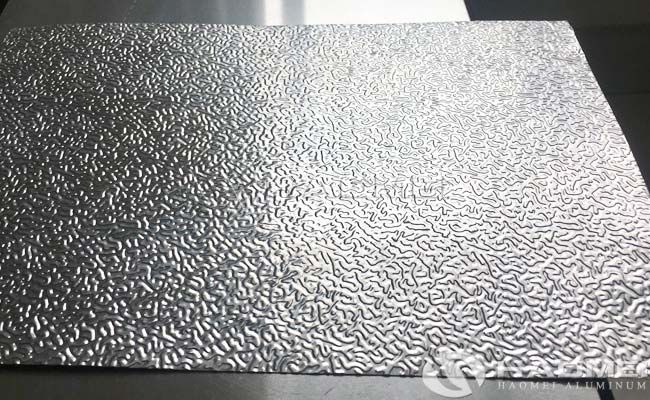

Orange peel aluminum sheet is divided into classic orange peel aluminum sheet and variation orange peel aluminum sheet (also known as insect pattern aluminum sheet). Its surface shows a pattern similar to orange peel, so it can also be called orange peel pattern aluminum sheet. Orange peel aluminium sheet is a series of stucco embossed aluminum sheet products commonly used in refrigerators, air conditioners, air duct and pipeline, tank insulation packaging.

Orange peel embossed aluminum coil (aluminum sheet) processing technology: parent roll - flattening - embossing - inspection - winding - packaging. The embossing machine for orange peel aluminum sheet is made of high-strength steel forging, because of its high strength, the deformation is small when pressing the pattern, and the extruded pattern is full and uniform in thickness. The orange peel stucco embossed aluminum sheet product offered by Haomei Aluminum are 1060 orange peel aluminum sheet and 3003 orange peel aluminum sheet.

1060 orange peel aluminum sheet is made of pure aluminum, which requires high formability, but not high requirements for strength and corrosion resistance. 1060 orange peel aluminum sheet is relatively cheap because of its simple manufacturing process, so it is usually used in pipeline jackating insulation. 3003 orange peel aluminum sheet is made of aluminum-manganese alloy, which is mainly used in the environment where good formability and high corrosion resistance are required for processing. 3003 stucco embossed aluminum sheet has a longer service life because of its better corrosion resistance.

The orange peel aluminum sheet for pipe insulation has many advantages. First, it reduces light pollution, because the surface of the aluminum sheet is divided into several refraction points after embossing, which scatters sunlight and makes it less dazzling to the naked eye. After orange peel embossing, it is processed into aluminum tiles and covered with kraft paper on the surface. After embossing, the overall thickness is increased, and the hand feel is thicker and much thicker. The strength of the aluminum coil is further increased after embossing and rolling again.

live:onlinehcx