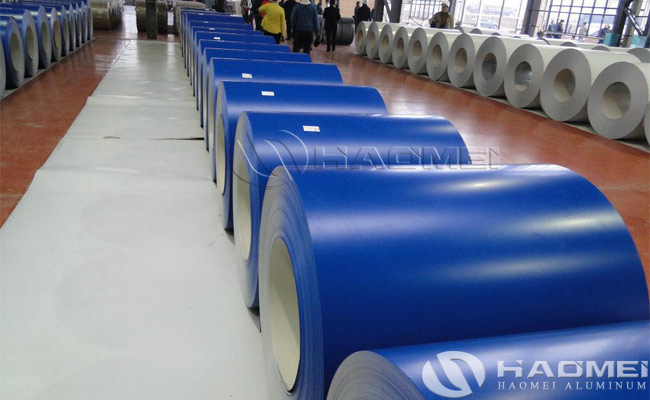

Painted aluminum sheet metal suppliers produce color coated aluminium with single coating (4μm-20 μm), double coating (25μm-28 μm) and 3 coating (35μm-38μm). The surface of painted aluminum sheet has various patterns, such as wood grain coated aluminum coil, stone grain coated aluminum coil, brick patterns coated aluminum sheet, camouflage aluminum coil, etc. Because of different uses, the color painted aluminum sheet metal are applied as roofing materials (aluminum-magnesium-manganese roofing system), ceiling materials (aluminum alloy ceilings), and brushed painted aluminum sheets (surfaces are processed by drawing). The price of color coated aluminum sheet is also affected by coatings. For example, polyester coating, PVDF coating, PE coating and powder coating are used for coating, and the quotation of pre-rolled aluminum sheet will be affected.

Coating is a key process in the aluminum coil coating production line of painted aluminum sheet metal suppliers. The quality of color coated aluminum products, especially the appearance quality, directly affects the decoration function of the product.

1, Coatings and aluminum coils are the key factors affecting the quality of the entire painting process.

Because of the color difference of the paint batch number, the insufficient particle size of the color coated aluminum sheet metal paint, the low coating rate, and the lack of safety of the paint with the organic solvent and its gradation, the actual effect of painting will be immediately impaired and defects will be formed.

2, The preparation of the coating line requires that the coating line equipment is in good condition, and the coating line equipment is running smoothly, without horizontal and straight jitter, and the coating line roller needs to be finely ground. In order to smoothly operate the coating equipment, the roller needs to be horizontally and vertically swayed and finely polished. The lateral runout of each roller of the coating machine must be controlled within the permitted range, otherwise it will seriously affect the surface quality of the coating.

3, The painting room should be clean, dust-proof, insect-proof, and ventilated to ensure that the quality of the painting surface is not polluted. At the same time, because of the change in temperature, the process conditions also change.

4, The painted aluminum sheet metal suppliers grasp the information of spraying technology and standardizing the actual operation is the key to achieving high-quality spraying effect. Therefore, it is necessary to strengthen the learning and training of operators, so that they can grasp the basic principles and key points of spraying technology, strengthen their sense of responsibility, and strictly follow the safety operation regulations to carry out actual operations to ensure the high quality of painted aluminum sheet products.

live:onlinehcx