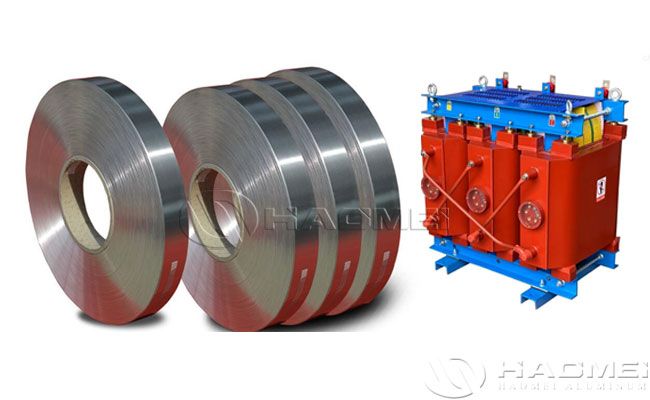

The round edge transformer aluminum strip usually refers to the aluminum strip used to manufacture transformer windings. Its corners are rounded to reduce edge scratches, stress concentration and other problems that may occur during use. Transformer aluminum strip is the main material for transformer coil winding. Its excellent electrical conductivity can effectively transmit current and reduce current loss. Compared with copper strip, aluminum strip has lower cost, so it is widely used in some low-voltage transformers.

Basic characteristics of round edge transformer aluminum strip:

- Material: Transformer aluminum strip is usually made of pure aluminum or aluminum alloy, with good electrical conductivity, thermal conductivity and corrosion resistance.

- Alloy and temper: Depending on the use, transformer aluminum strip has different brands, specifications and states. Common brands include 1060, 1050, 1070, 1350, etc. The temper is usually O state (soft state), and the hardness and annealing degree can be indicated by numbers.

- Size: The thickness of transformer aluminum strip is generally between 0.08-3.00mm, and the width can reach 20-1650mm to meet the manufacturing needs of different transformers.

The manufacturing of transformer aluminum strips usually adopts rolling, stretching, annealing and other processes to ensure that they have good electrical conductivity, thermal conductivity and mechanical properties. High-end transformer aluminum strips usually use cutter milling or special chamfering machines to round the edges of the aluminum strips.

Reasons for rounding:

- Prevent insulation damage: The sharp edges of aluminum strips are easy to scratch the insulating material, and rounding prevents winding short circuit.

- Reduce stress concentration: rounded corners disperse the stress generated by electromagnetic force and prevent material fatigue cracking.

- Optimize electric field distribution: In high-voltage environments, rounded corners can avoid electric field concentration and reduce the risk of partial discharge.

- Improve heat dissipation: Smooth edges promote the flow of cooling medium and improve heat dissipation efficiency.

Advantages of rounded edge of aluminum strip for transformer winding:

- Improve safety: Reduce the risk of winding short circuit and insulation failure.

- Extend life: Reduce material aging caused by mechanical stress and electrical stress.

- Enhance reliability: Uniform electric field and heat dissipation improve transformer stability.

- Process optimization: Facilitate winding operation, reduce equipment wear, and improve production efficiency.

Application scenarios of round edge transformer aluminum strip:

- High-voltage/large-capacity transformers: high requirements for electric field uniformity, and rounded corners are more necessary.

- Frequent load change scenarios: need to cope with greater electromagnetic stress, and rounded corners enhance structural strength.

live:onlinehcx