Cut to size at customers' need !

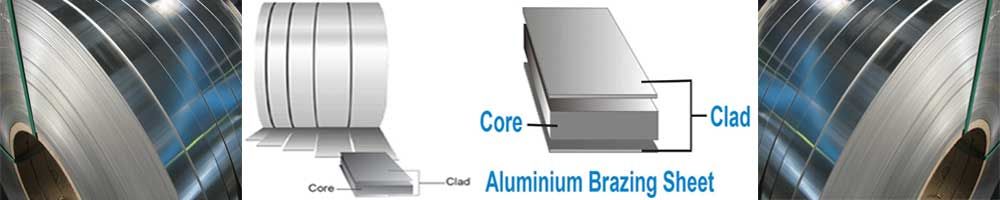

Add to Product FavoritesAluminum cladding/brazing sheet is the key material of air separation equipment and heat exchanger. It is made of cladding alloy with single or double cladding matrix alloy which is rolled by composite rolling.

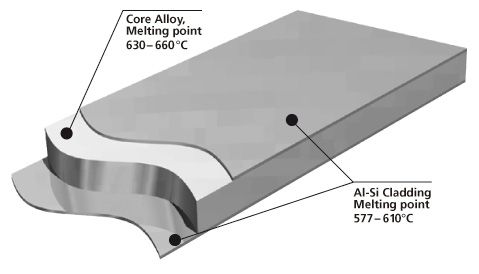

Brazing sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum-silicon (Al-Si) alloy. This thin layer, usually makes up 5 % to 10 % of the total thickness of the brazing sheet. It melts and flows during the brazing process, to provide upon cooling a metallic bond between the components.

1, Brazing layer materials: Al-Si(4000 series aluminum alloy,like 4045, 4047, 4104, 4343)

2, Sacrificial anode material(Anticorrosive coating): AL-Zn-Cr(7072, etc.)

3, Brazing core material: Al-Mn(3000 series aluminum alloy, 3003, 3005, 3105),

Al-Si-Mg(6000 series alumuinum alloy, 6063)

Clad aluminum sheet/strips for brazing, which are widely used in brazed heat exchangers, electronics, automotive engineering, thermal engineering, and machinery engineering and etc.

The normal alloys are 4045/3003, 4343/3003, 4045/3003/4045, 4343/3003/4343, 4343/3003/7072 and etc.

Dimensions | ||

Type | Strips | Sheets |

Thickness | 0.051mm--3.0mm | 0.4mm--6.35mm |

Width | 6mm--1600mm | 500--1600mm |

Length | - | Max. 10000mm |

Edge quality | Trimmed | Trimmed and slit; sawn |

Inside diameter | 305mm, 405mm, 505mm Paper core, | - |

Outside diameter | Max. 1600mm without connect point | - |

| |||

Cladding | One side; Both sides | ||

Cladding rate | 5%, 7.5%, 10%, 13%, 15% (other clad percentages | ||

Cladding tolerance | Cladding thickness of 1.5%--<4%: +/-0.6 | ||

Surface | |

Quality | Mill finish; for thickness 0.3--3.5mm, chemically degreased |

Marking | Ink marking |

Clad Rate: 8%-12% per side or customer requested

Application: the material widely used for manufactuer radiators, condensers, evaporators,heat exchanger, intercoolers, engine oil coolers etc.

Min Order: 3 ton per size as trial

Delivery Time: within 15-25days after receipt of your deposit

Packing : export standard wooden box or pallet.

Heat transfer rate: good thermal conductivity to dissipate heat

Corrosion resistance performance: cannot be corroded by refrigerant or coolant

Strength: high strength,

Weight: as light as possible,

Anti-sag performance: no high-temperature buckling during brazing

Aluminium brazing sheet is manufactured by roll-bonding techniques to clad a core alloy ingot on one side or both sides with a low melting AlSi alloy. As an alternative, one side can be clad with a non-braze alloy, e.g. Zn-containing alloy.

Depending on the desired final properties, the core is either homogenized or not before the cladding operation.

The whole package is subjected to preheating, hot rolling and cold rolling down to the final thickness of the respective products. Depending on the requested final properties, the material is subjected to final annealing and / or intermediate annealing operation(s).

Aluminum products of Haomei Al. meet the export standard. Plastic film and brown paper can be covered at customers’ need. What’s more, wooden case or wooden pallet is adopted to protect products from damage during the delivery. There are two kinds of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience. Generally speaking, there are 2 tons in one package, and loading 18-22 tons in 1×20′ container, and 20-24 tons in 1×40′ container.

Product Lists

Breif Introduction of Us

Haomei Aluminum

live:onlinehcx