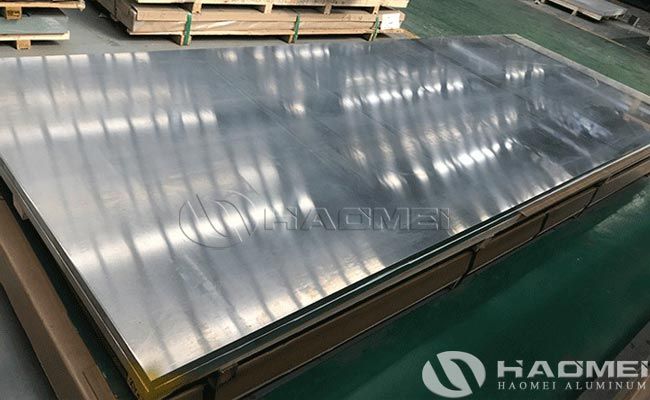

Aluminium sheet 5083 h111 is a high strength, good corrosion resistance and common aluminium sheet alloy material. 5083 H111 aluminium plate has a wide range of application areas, in the need for corrosion resistance, high strength and lightweight materials are better performance. It is commonly used in the manufacture of ships, offshore platforms, hull structures, tankers and other fields.

Aluminium sheet 5083 h111 is mainly composed of aluminium, magnesium and a small amount of other elements, which has good corrosion resistance and strength. The H111 temper is a softened state of aluminium sheet, which has a lower strength and is suitable for some applications that require better corrosion resistance. Thicknesses usually range from 1mm to 200mm, with common thicknesses of 1mm, 2mm, 3mm, 5mm, 6mm, 8mm, 10mm, 15mm and 20mm. Width is usually between 1000mm and 2600mm, common widths are 1000mm, 1220mm, 1500mm, 2000mm, etc. The length is usually between 2000mm and 12000mm, and different lengths can be customised according to the customer's demand. 5083 aluminium sheet specifications can be customised according to the customer's demand and the production capacity of the manufacturer.

The production process of 5083 H111 aluminium sheet usually includes the following steps:

1. Preparation of raw materials:

Select high-purity aluminium alloy raw materials, the main components are aluminium, magnesium and a small amount of manganese. The raw materials are strictly inspected and screened to ensure that the quality meets the requirements.

2. Casting:

The raw material aluminium alloy is heated to a suitable temperature and cast into the initial shape of the plate by casting equipment.

3. Rough rolling:

The aluminium plate after casting is rough rolled and pressed into the required plate thickness by rolling equipment.

4. Hot Rolling:

After rough rolling, the aluminium plate is hot rolled, and then heated and rolled again by the rolling equipment, so as to form a more uniform plate thickness.

5. Annealing treatment:

5083 H111 aluminium sheet needs to be annealed after hot rolling, by controlling the heating temperature and cooling speed, to eliminate internal stress and improve the strength and toughness of the plate.

6. Surface treatment:

5083 H111 aluminum sheets are subjected to surface treatment, such as polishing, oxidation, sandblasting, etc., to improve their appearance quality and corrosion resistance.

7. Testing and Packing:

Strict quality testing is carried out on the produced 5083H111 aluminium plates, including chemical composition, mechanical properties and other aspects of the test. After qualified, it is packed and ready for shipment.

In general, aluminium sheet 5083 h111 has good corrosion resistance and low strength, which is suitable for marine engineering and other fields that require high corrosion resistance. When choosing 5083 H111 aluminum sheet, you need to consider it according to the specific use requirements and application scenarios.

live:onlinehcx