Polysurlyn moisture barrier embossed aluminum coil is actually a composite insulation material that combines the high strength of aluminum coil with the excellent moisture barrier performance of Surlyn film.

Material composition of embossed aluminum coil with polysurlyn moisture barrier:

1. Aluminum coil substrate

The commonly used materials are 1060 pure aluminum or 3003 aluminum-manganese alloy, with a thickness range of 0.3-2.0mm and a width of 800-1300mm. The aluminum coil itself has good corrosion resistance. 3003 alloy contains manganese, which is particularly suitable for high humidity or corrosive environments (such as chemical plants and coastal areas).

2. Polysurlyn (Surlyn film) moisture barrier

- Material characteristics: Surlyn film is an ionomer (ethylene-methyl methacrylate copolymer) produced by DuPont, which is combined with aluminum coil through a hot pressing composite process. The thickness is about 0.076mm and the weight per square meter is 0.08kg. Its unique structure includes:

- The first layer: dense film, no more than 5 water seepage holes in 10 moisture-proof test holes, and excellent waterproofness.

- The second layer: a one-way water-absorbing film that absorbs water vapor around the aluminum material and releases it irreversibly to prevent internal corrosion.

- The third layer: the adhesive film layer, which enhances the bonding strength with the aluminum coil and can withstand harsh conditions such as hot water and low temperature for a long time.

- Performance advantages: temperature resistance range -40℃ to +360℃, resistance to chemical corrosion (such as acid and alkali), and still maintains bonding performance after thermal aging.

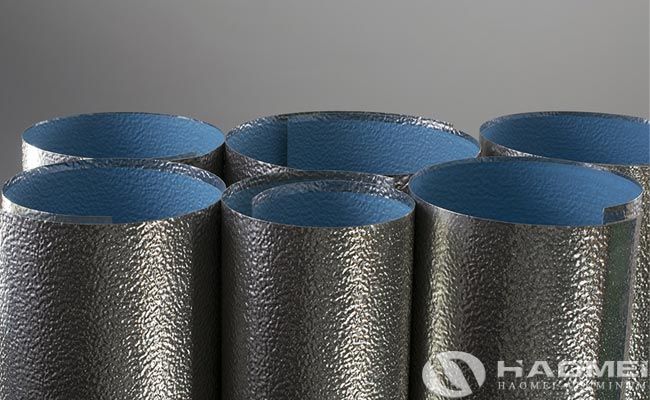

3. Embossing design

Common embossing types are orange peel patterns (worm patterns), with an embossing depth of 0.1-0.15mm. Through two-roll mill processing, the surface hardness and wear resistance of the aluminum coil are enhanced, while the aesthetics are improved. The thermal conductivity and heat dissipation performance of the orange peel aluminum coil are good, and it is suitable for pipe insulation and refrigeration equipment.

Technical parameters of polysurlyn moisture barrier embossed aluminum coil:

- Thickness: 0.3-2.0mm for aluminum coils, 0.076mm for sarin film.

- Width: 800-1300mm, can be customized in narrow widths (such as 50-meter small rolls for easy construction).

- Mechanical properties: tensile strength 170-305MPa, elongation at break 180%, bending strength 2MPa, compressive strength 160MPa.

- Fire rating: Class B flame retardant, in line with building exterior wall insulation requirements.

Embossed aluminum coils with Polysurlyn moisture barrier in insulation materials have the following advantages:

- Excellent moisture barrier performance:

Polysurlyn moisture barrier can effectively prevent moisture penetration, protect insulation materials from moisture, and reduce heat loss and material degradation caused by moisture.

- Enhanced corrosion resistance:

Aluminum itself has good corrosion resistance, and with the Polysurlyn layer, it can further improve the overall durability and extend the service life.

- Good heat reflectivity:

Aluminum coils can effectively reflect heat, improve insulation effect, and reduce energy consumption, especially in air conditioning and heating systems.

- Beautiful surface treatment:

The surface treatment of embossed aluminum coils not only increases the aesthetics, but also improves the friction of the material and reduces the risk of sliding, making it suitable for various construction and decoration occasions.

- Lightweight and easy to process:

Embossed aluminum coils are usually lighter, easy to cut and install, suitable for quick installation at the construction site, saving time and labor costs.

- Good mechanical strength:

Embossed treatment enhances the surface strength of the aluminum coil, can withstand certain mechanical shock and pressure, and is suitable for use in various environments.

- Environmental protection:

Aluminum is recyclable and meets modern environmental protection requirements. The use of this material helps to reduce the impact on the environment.

- Versatility:

It can be widely used in many fields such as construction, pipeline insulation, refrigeration equipment, etc., with strong adaptability.

Application areas of polysurlyn moisture barrier embossed aluminum coil:

1. Industrial insulation

- Outer sheath of oil and natural gas pipelines, especially pipeline projects exported to Middle Eastern countries.

- Insulation of tanks and equipment in power plants and chemical plants, 3003 aluminum alloy material can resist corrosion in the desulfurization environment.

2. Construction engineering

- Roof and wall insulation layer, moisture-proof layer can prevent water vapor from penetrating and damaging insulation materials.

- Insulation protection of cold storage and air-conditioning systems, orange peel grain design takes into account both heat dissipation and mechanical strength.

3. Special scenarios

- In high-altitude and high-temperature difference areas, the aluminum jacketing with polysurlyn moisture barrier can operate stably in an environment of -20℃ to +45℃.

- In coastal high salt fog environment, the 3003 aluminum alloy + polysurlyn film combination can withstand 1000 hours of salt fog test.

Procurement suggestions

1. Material selection: 1060 pure aluminum is used in general environment, and 3003 aluminum alloy is selected for high corrosion environment.

2. Embossing customization: Choose orange peel pattern or other patterns (such as diamond pattern) according to design requirements, and the mold needs to be opened 15 days in advance.

3. Certification standards: Suppliers are required to provide ISO 9001 certification and moisture-proof performance test reports (such as GB/T 10125 salt fog test).

live:onlinehcx