Aluminium cladding for pipe insulation is typically manufactured using alloys AA 3003, 3105, 1050, 1060, 1070, 5052, 5005 which are widely used for the purpose of insulation jacketing. Most common used alloy for insulation are 1060 and 3003 H14 H16. 3003 is better in anti-rust performance than 1060.

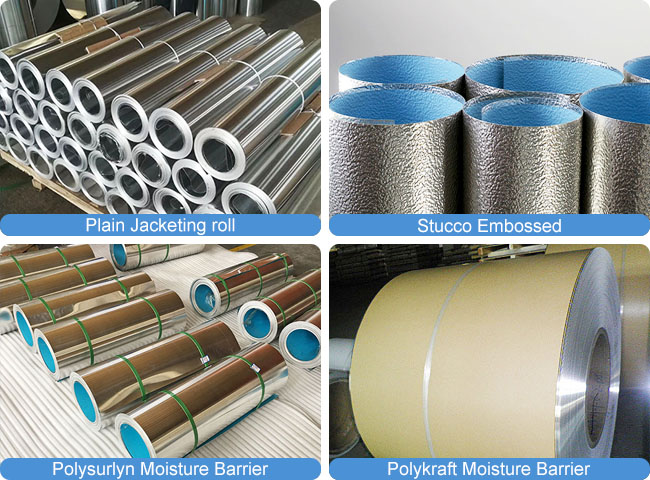

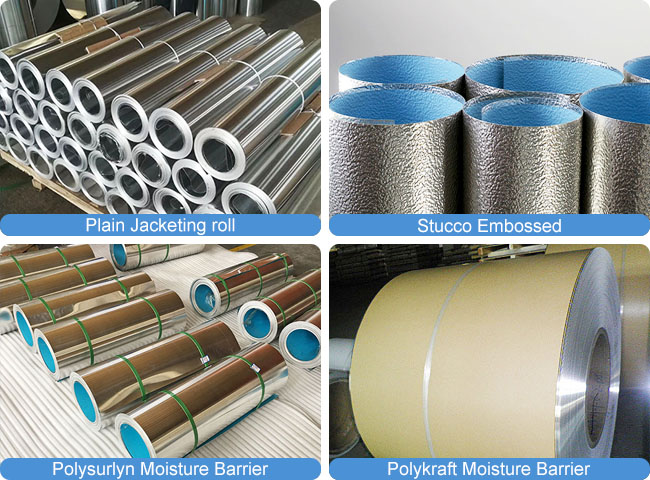

Aluminum cladding for pipe insulation is available in Smooth, Stucco Embossed, with or without moisture barrier (craft paper and poly surlyn).

Grade: 1006, 1100, 3003, 3105, 5005

Temper: O, H12, H14, H16, H24, etc.

Common use: 3003 H14 H16, 1100 H14 H16, 5005 H14

Type: Coil roll

Application: Industrial insulation jacketing, cover, insulation protective jacketing

Thickness: 0.3-1.5mm

Width: 914mm, 1000mm, 1219mm

Length: 20, 25,30, 60, 90m per roll or as per clients

Surface Treatment: Plain, Flat, mill finish, Embossed

Moisture barrier: polysurlyn, craft paper

Certificate: ISO9001, GB/T3880, ASTM B209

Packaging: packed in carton or coil in wooden pallet

Delivery time: 25-45 days

Minimum order quantity: 2 tons

Specification of aluminium cladding for insulation

|

Alloy |

|

Thickness(inch) |

Thickness(mm) |

Width(mm) |

Length(m) |

Suggested Application |

|

1100, 1060, 3003, 3105, 5005 |

H14, H16 |

0.012 |

0.3 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.016 |

0.4 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.020 |

0.5 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.024 |

0.6 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD 36"-8′ (914mm-2.43m) insulated pipe lines&equipment. |

|

0.032 |

0.8 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

special applications where extra thickness and protection is required, such as fabricated tank head covers and other special fabrications. |

|

0.040 |

1.0 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

special applications where heavy mechanical is required. |

|

0.050 |

1.2 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

flat ducts or precipitators. Also recommended for areas subject to high wind conditions. |

Remarks: Other sizes available upon request.

Chemical Composition of aluminium pipe cladding

|

Alloy |

Si |

Fe |

Cu |

Mn |

Zn |

Mg |

Ti |

Cr |

Other Elements |

Al |

|

|

Each |

Total |

|

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.05 |

0.03 |

0.03 |

- |

0.03 |

|

99.6min |

|

1100 |

Si+Fe=0.95 |

0.05-0.20 |

0.05 |

0.10 |

- |

- |

- |

0.05 |

0.15 |

99.0min |

|

3003 |

0.6 |

0.7 |

0.05-0.20 |

1.0-1.50 |

0.10 |

- |

- |

- |

0.05 |

0.15 |

reminder |

|

3105 |

0.6 |

0.7 |

0.30 |

0.30-0.80 |

0.40 |

0.20-0.80 |

0.10 |

0.20 |

0.05 |

0.15 |

reminder |

|

5005 |

0.3 |

0.7 |

0.20 |

0.20 |

0.25 |

0.50-1.10 |

- |

- |

0.05 |

0.15 |

reminder |

Classification of insulation aluminium cladding

Smooth Aluminum Jacketing

1.Shed rain water the best

2. Show damage such as physical abuse.

3. Show the dirt due to its smoothness.

4. It is highly reflective of sunlight

Stucco embossed Aluminum Jacketing

1, Increase its strength and ductility

2, Extend its lifetime

3, Better bribability, durability

4, Effectively reduce rowing

5, Not cause strong light reflecting

6, Have a good vision effect

Aluminum Jacketing with Moisture barrier

Haomei Aluminum Jacketing products can be supplied with a 40# kraft (1 1/2 mil polyethylene) or a 3 mil polysurlyn moisture retarder which is heat and pressure bonded to the interior surface. A moisture retarder helps prevent galvanic corrosion caused by contact of dissimilar metals in the presence of moisture or chemical corrosion caused by installing sheets over damp insulation materials.

Benefit: Moisture barrier prevents corrosion and protect inner insulation materials

Aluminum jacketing laminated with polysurlyn

Poly surlyn : Dupont surlyn, 3 mil thickness(76um)

Color: Bule

Aluminum sheet thickness : 0.3-1.0mm

Package: 20-30m/roll in one carton or big coil

Advantage: water-proof, prevent oxidation

Aluminum jacketing laminated with kraftpaper

Kraft-paper: 166g/m2

Color: khaki

Aluminum sheet thickness: 0.3-1.0mm

Package: 20-30m/roll in one carton or big coil

Advantage: water-proof, prevent oxidation

Features of aluminum pipe cladding

1.Customized packaging solutions for extended shelf life

2.Excellent barrier against moisture, oxygen & odour

3.Excellent mechanical properties even at low thickness

4.High burst strength and puncture resistant.

Application of aluminum cladding

Aluminum Jacketing is recommended for use in all of the following insulation system applications:

• Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks.

• Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired.