Commonly used lacquered aluminum sheet for closure caps are 8011 aluminum sheet and 3105 aluminum sheet, etc., which are widely used in the sealing packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc. The performance parameters such as strength, flatness, elongation, and dimensional deviation of the aluminum sheet for closure caps are strictly required, and in order to facilitate later printing, the requirements for the oil removal rate of the closure sheet material are also very high.

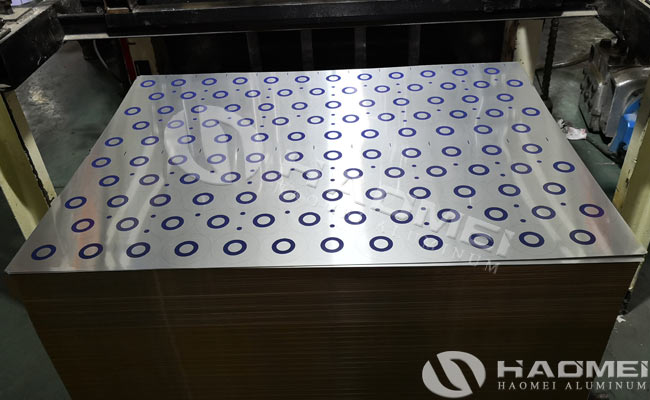

The lacquered aluminum sheet for closure caps has thickness range of 0.15-0.27mm, thickness tolerance ±0.005mm, width within 330-1000mm, width tolerance ±1mm, tensile strength 150-165Mpa, elongation >2%, fine surface, no obvious roll pattern, no obvious black Lines, oil spots, ash inclusions, scratches, bright strips and other defects, the ear-making rate is controlled within 3%, and the aluminum closure sheet material process should go through cold rolling - foil rolling annealing thickness - annealing - foil rolling finished products - stretch bending straightening —Slitting and other processes are completed. After the finished aluminum roll is produced, it must go through multiple processes such as cutting, painting, drying, multiple stamping, and anti-counterfeiting labels to finally produce qualified bottle caps.

The advantage of lacquered aluminium sheet for closure caps is that the water level is brushed and the ear-making rate is low. For later caps manufacturing, Dos oil is also needed. DOS Oil - Dioctyl Sebacate, chemical name, dioctyl sebacate is a colorless, odorless, or light yellow transparent liquid. It is widely used in tinplate coil, tinplate (ETP), chrome plate coil (TFS) and aluminum foil for the needs of rust prevention, lubrication and improvement of stamping of raw materials for food packaging containers.

Lacquered aluminum sheet for closure caps not only have excellent sealing performance to prevent leakage of contents, but also have strong adaptability, can print colorful patterns, and are easy to achieve mass production. In addition, the low cost of the aluminum cover can save costs.

live:onlinehcx