Cut to size at customers' need !

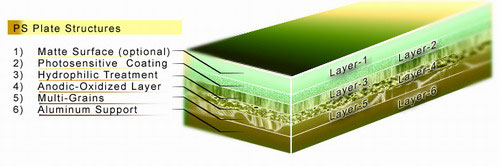

Add to Product FavoritesPS plate is the abbreviation of presensitized offset plates, PS plate can adapt to the development of lithography well. PS plate has high resolution, full dot reproduction, rich levels, and ink balance easy to master, stable performance, fast sensitivity, large development latitude, high printing resistance etc characteristics.

According to the printing process, the type of sensitizer applied in the of PS plate is divided into positive type and negative type. The positive type is printed down with the positive original, to make the positive PS plate for printing on the machine; the negative type is printed down with the negative original, to make the negative PS plate for printing on the machine.

Product Name | PS Plate |

Color | Blue/Green |

Processor | All the kind Brands |

Developer | Any PS plate developer or our own developer |

Aluminum Base Alloy temper | 1060, 1050A, 1100 H18 |

Thickness | 0.15-0.4mm(0.15/0.20/0.25/0.30/0.40mm) |

Sizes | 570*510, 650*550, 670*560, 680*640, 730*605, 745*605, 755*625, 830*670, 915*715, 920*760, 1030*770, 1030*785, 1030*790, 1030*795, 1030*800, 1030*820, etc. Or according to customer’s requires |

Maximum width | 1350mm |

Surface Roughness | 0.5-0.8um |

Plate base color density | ≤0.01 |

Mass per unit area of anodized layer | 2.5-3.0g / m² |

Mass per unit area of photosensitive layer | 2.2-2.3g / m² |

Sensitivity/Exposure energy | 100-140mj / m² |

Spectral Sensitivity/Photosensitive wavelength | 300-550nm |

Exposure Duration | 30 seconds, about 20 pulses |

Developing time | 20-30 seconds |

Developing temperature | 22-25 ℃ |

Resolution | 2-99% at 200lpi |

Safety light | Under yellow light |

Run Length | Standard plate making 50,000-100,000 impressions, Baked plate ≥200,000 impressions |

Storage period | 24 months, protected from light, moisture and heat |

Storage conditions | Temperature ≤30 ℃, relative humidity ≤65 ℃, stacking height ≤1.5 meters |

Note: Samples available, all sizes can be supplied according to customer's demand.

1. Multi layer grains, smooth coating, high sensitive speed, excellent dot reappearance, large exposure and developing latitude, quick ink water balance, long impression

2. Abrasion resistant grains, precise size, excellent dot reappearance, quick ink water balance, super long impression

3. Economical printing, high-sensitive speed, perforation by international standard

4. Unique and Smooth Photosensitive Coating-High Sensitivity

5. Rough Gas-leading Layer

6. Excellent dot reproduction

PS Plate is suitable for all the mainstream printing down machines, developing machines and developer, widely used in all kinds of graphic offset printing.

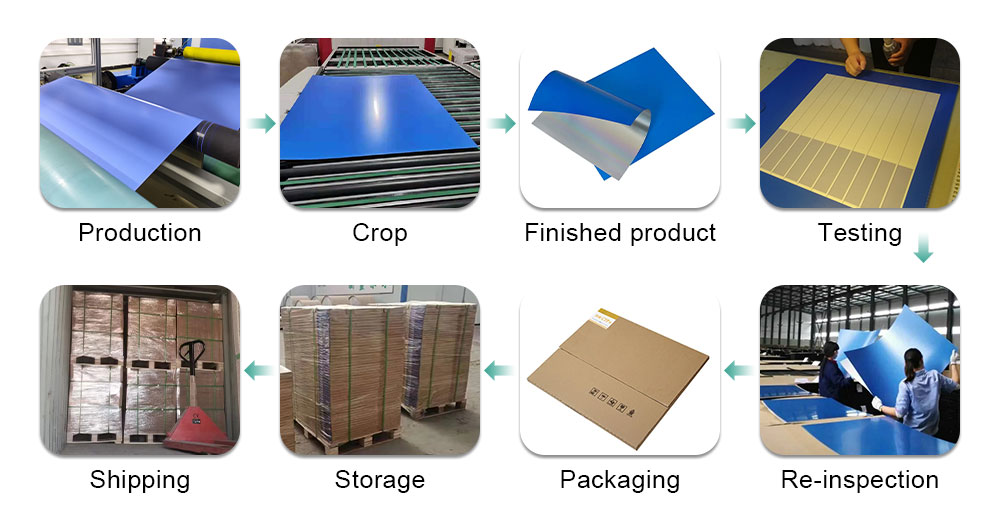

Two coated faces are placed facing each other, separated by neutral backing paper in the middle, the outside is covered with plastic lined black Kraft paper and placed in the carton box, each carton box is loaded around 50 -100 pieces,

Then stack the loaded carton boxes neatly on the wooden pallet and protect them with wooden frames or cardboard.

Finally, wrap it with kraft paper or plastic film and tighten by plastic tapes.

Or Packed according to customer requirements.

Aluminum products of Haomei Al. meet the export standard. Plastic film and brown paper can be covered at customers’ need. What’s more, wooden case or wooden pallet is adopted to protect products from damage during the delivery. There are two kinds of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience. Generally speaking, there are 2 tons in one package, and loading 18-22 tons in 1×20′ container, and 20-24 tons in 1×40′ container.

Product Lists

Breif Introduction of Us

Haomei Aluminum

live:onlinehcx