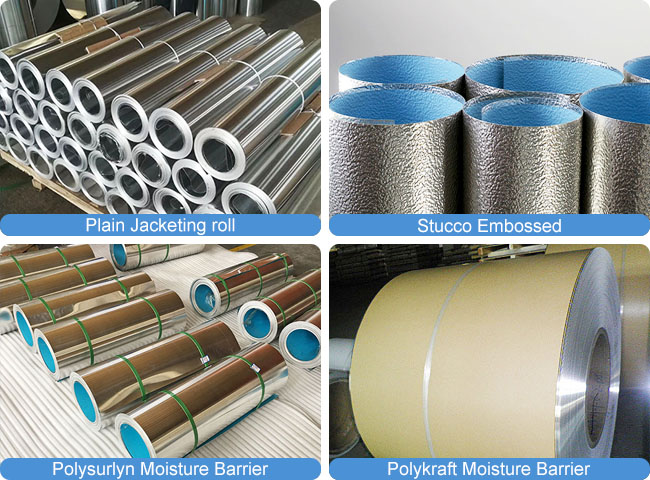

Haomei offers aluminum jacketing, banding and other accessories to be used in any commercial and industrial insulation applications. These products are designed for pipe insulation and protection in just about any setting. It protects the insulation and underlying pipe from physical damage, UV exposure, corrosive atmospheres, and water.

Aluminium jacket is typically manufactured using alloys AA 3003, 3105, 1050, 1060, 1070, 5052, 5005 which have very similar composition and performance and are considered interchangeable for widely used for the purpose of insulation jacketing.

Grade: 1006, 1100, 3003, 3105, 5005

Temper: O, H12, H14, H16, H24, etc.

Common use: 3003 H14 H16, 1100 H14 H16, 5005 H14

Type: Coil roll

Application: Industrial insulation jacketing, cover, insulation protective jacketing

Thickness: 0.3-1.5mm

Width: 914mm, 1000mm, 1219mm

Length: 20, 25,30, 60, 90m per roll or as per clients

Surface Treatment: Plain, Flat, mill finish, Embossed

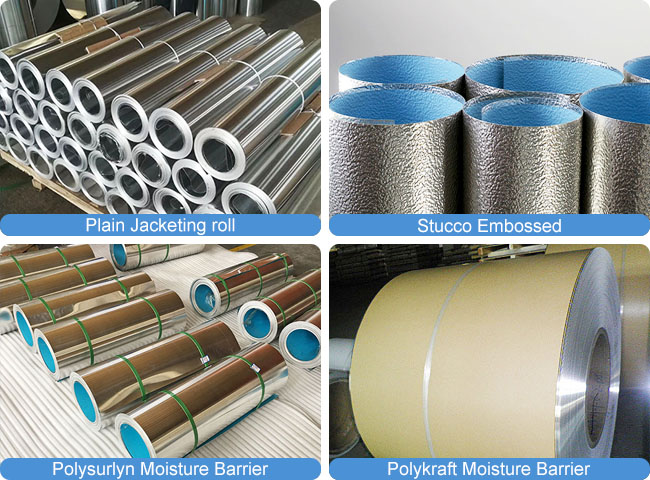

Moisture barrier: polysurlyn, craft paper

Certificate: ISO9001, GB/T3880, ASTM B209

Packaging: packed in carton or coil in wooden pallet

Delivery time: 25-45 days

Minimum order quantity: 2 tons

Specification of aluminum jacket for pipe insulation

|

Alloy |

|

Thickness(inch) |

Thickness(mm) |

Width(mm) |

Length(m) |

Suggested Application |

|

1100, 1060, 3003, 3105, 5005 |

H14, H16 |

0.012 |

0.3 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.016 |

0.4 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.020 |

0.5 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD below 36"(914mm) insulated pipe lines. |

|

0.024 |

0.6 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

OD 36"-8′ (914mm-2.43m) insulated pipe lines&equipment. |

|

0.032 |

0.8 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

special applications where extra thickness and protection is required, such as fabricated tank head covers and other special fabrications. |

|

0.040 |

1.0 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

special applications where heavy mechanical is required. |

|

0.050 |

1.2 |

914, 1000, 1219 |

20, 25,30, 60, 90, coil |

flat ducts or precipitators. Also recommended for areas subject to high wind conditions. |

Remarks: Other sizes available upon request.

Chemical Composition of aluminum jacketing

Commercially pure aluminum is relatively soft and less suited for use in this application. Its strength can be greatly improved by alloying with small percentages of one or more other elements such as manganese, silicon, copper, zinc, and magnesium. Additional strength can be achieved by cold working. Haomei aluminum metal jacketing have the highest quality, are corrosion resistant, and comply with all relevant standards.

|

Alloy |

Si |

Fe |

Cu |

Mn |

Zn |

Mg |

Ti |

Cr |

Other Elements |

Al |

|

|

Each |

Total |

|

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.05 |

0.03 |

0.03 |

- |

0.03 |

|

99.6min |

|

1100 |

Si+Fe=0.95 |

0.05-0.20 |

0.05 |

0.10 |

- |

- |

- |

0.05 |

0.15 |

99.0min |

|

3003 |

0.6 |

0.7 |

0.05-0.20 |

1.0-1.50 |

0.10 |

- |

- |

- |

0.05 |

0.15 |

reminder |

|

3105 |

0.6 |

0.7 |

0.30 |

0.30-0.80 |

0.40 |

0.20-0.80 |

0.10 |

0.20 |

0.05 |

0.15 |

reminder |

|

5005 |

0.3 |

0.7 |

0.20 |

0.20 |

0.25 |

0.50-1.10 |

- |

- |

0.05 |

0.15 |

reminder |

SURFACE FINISHES

Each of the three surface finishes available for ITW Aluminum Jacketing (smooth, stucco embossed, and 3/16”corrugated has applications where it is recommended. All of these can be supplied with a painted exterior. For more information on this, consult the ITW data sheet on painted aluminum jacketing.

Smooth (Plain Mill) Finish

This is a very popular finish and is the “default” for the many end-users/specifiers who prefer the clean look of this finish.

This finish sheds rain water the best. However, this smooth surface readily shows damage such as from hail or other physical abuse. It is also shows the dirt more than the other finishes due to its smoothness. Lastly, it is highly reflective of sunlight and when located near roadways, some specifiers

see this reflection as a possible safety hazard.

Stucco Embossed Finish

This is another popular finish used for aluminum jacketing. The stucco-like surface texture hides small imperfections and scratches caused by physical damage during or after installation. This finish also reduces reflectivity while still looking very professional. Lastly, the use of stucco embossed finish provides a small increase to the rigidity and strength of the aluminum jacketing.

Moisture barrier

Polysurlyn

Polysurlyn Moisture Barrier (PSMB) is an engineered three layer coextruded film of polyethylene and DuPont Surlyn polymers with a total film thickness of 3 mils (76 μm). PSMB is heat laminated in the factory to the interior surface of all types of aluminum metal jacketing for mechanical insulation to help prevent pitting, crevice, and galvanic corrosion of the interior surface of the aluminium metal jacketing and the underlying insulated pipe, tank or equipment. Due to its superior performance characteristics, PFMB replaces the old moisture barrier technology of 1 to 3 mil thick polykraft.

Polykraft

Polykraft (PKMB) consists of one layer of one mil polyethylene film with a protective layer of 40# virgin kraft paper. The moisture barrier is factory applied by attaching the aluminum jacketing by continuous lamination to the full width of the metal. The moisture barrier is used to prevent moisture and corrosives in the insulation from coming into direct contact with the aluminum metal jacketing surface and causing galvanic or chemical corrosion.

Features of Aluminum Metal Jacket

1.Customized packaging solutions for extended shelf life

2.Excellent barrier against moisture, oxygen & odour

3.Excellent mechanical properties even at low thickness

4.High burst strength and puncture resistant.

Application of Aluminum Plain Jacketing roll

Aluminum Jacketing is recommended for use in all of the following insulation system applications:

• Standard outdoor use on all pipe, vertical tank insulation systems up to 8 ft outer diameter, and all horizontal tanks.

• Indoor insulation system applications up to 8 ft outer diameter where increased damage resistance is desired.

INSTALLATION:

INSTALLATION:

Aluminum Jacketing are used primarily as weather and UV protection for exterior pipe insulation. Aluminum jacketing is installed over straight pieces of pipe insulation and is fastened closed with fab-straps or screwed.