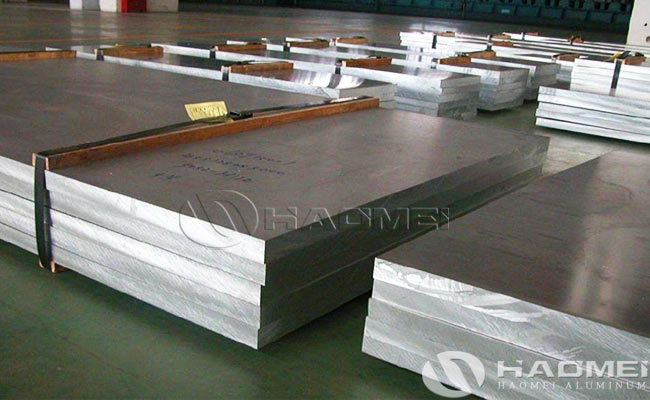

Aluminium plate manufacturer offer various aluminum plate with different processing method and grade to meet customers’ requirement. With the rapid development of economic construction and the wide application of aluminum products, the aluminum processing industry has also achieved quite impressive results, and the output of aluminum rolled products and aluminum rolled products has also been greatly increased. Although aluminum has flooded all aspects of our lives, many people still know less about how to classify aluminium plate and how to make them.

Generally speaking, what we call aluminum plate is just a general term, which refers to aluminum plate-shaped materials made of aluminum or aluminum alloy materials. The classification of aluminum plates is determined by the different processing methods used in the production process of aluminum materials. The aluminum plate is made by the process of heating, rolling, straightening, and solid solution aging heat.

1, Aluminum checker plate:

Aluminum checker plate is a kind of aluminum plate that is processed on the basis of aluminum plate by aluminium plate manufacturer, so that various patterns are formed on the surface of the aluminum plate. Checkered aluminum plates are mainly used in packaging, floor, toolbox, integrated ceilings and building curtain walls.

2, brushed aluminum plate:

The main process flow of brushed aluminum plate has three parts, which are de-esterification, sand mill and water washing. In the process of drawing the aluminum plate material, it is necessary to use sandpaper to perform repeated rubbing line treatment. After the treatment, the surface of the aluminum plate will clearly show a few fine wire marks, so as to achieve the metal drawing effect, and then pass through the anode. Treatment, in this way, a film layer containing special metal components will be formed on the surface of the aluminum plate, which can play a protective role such as anti-corrosion.

3, Anodized aluminum plate

The formation of the anodized aluminum plate undergoes an electrolytic oxidation process. First, the aluminum plate is placed in the electrolyte as the anode, and then the current is applied under certain conditions to carry out the electrolytic oxidation process, and finally a thin aluminum oxide layer can be formed on the surface of the aluminum plate. It seems very simple to say that, but in fact, the ordinary oxidation production process adopted by the general aluminium plate supplier, the process is more complicated, and the defective product rate is also relatively high.

4, Mirror aluminum plate:

Mirror finish aluminum plate needs to be processed by rolling technology, grinding and other methods to make the surface of the aluminum plate show a mirror effect. Mirror aluminum plate production in developed countries generally uses rolling to make coils.

The aluminum can be formed into various aluminum plates through different processing methods, and the quality of the processing method also determines the quality of the aluminum plate and the level of aluminium plate manufacturer. Haomei Aluminum is a large-scale aluminum plate manufacturer. The company's distribution of pure aluminum plates, 3003 aluminium plate, 5052 aluminum plates, 6061 aluminum plates and other products are complete and reasonable in price. Welcome everyone to inquire!

live:onlinehcx