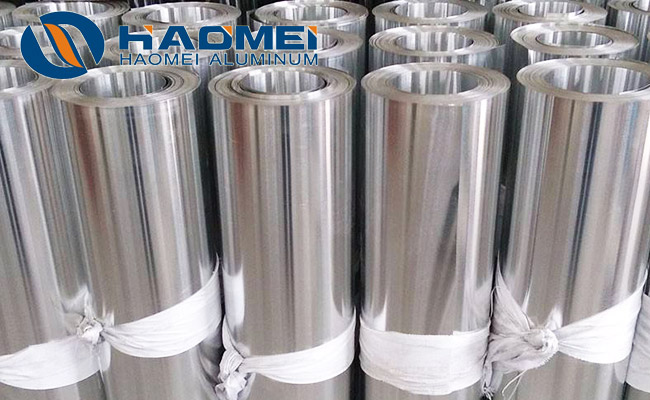

Aluminum jacketing for ductwork 1060 3003 has thermal insulation coefficient less than or equal to 0.12, which develop rapidly and are used in industry and architecture. Aluminium jacketing sheets are widely used in power plant desulfurization, flue thermal insulation, chemical plant, oil field petrochemical, nuclear power plant and other pipeline thermal insulation. As we all know, there are more and more aluminum cladding projects for thermal insulation. Many customers choose aluminum jacket as the first choice for thermal insulation pipeline projects. But many customers don't know the difference between the ASTM-B209 aluminum jacketing 1060 and 3003.

1, Alloy difference of aluminium jacketing

The difference in density is that the density of 3003 aluminum jacketing is 2.72, but the density of 1060 aluminum jacketing is 2.71. The difference between the two is not very big, it may just be a simple density difference of 0.01. However, if the work volume is large, the difference in weight is quite large. Therefore, when purchasing thermal insulation aluminum jacket sheet, customers must pay attention to the density that is more suitable.

2, Difference of antirust property of aluminum jacket sheet

Aluminum jacketing for ductwork is rust proof. Aluminum jacketing is different from iron cladding. If the iron cladding is bare on the surface, it will rust in a period of time, but aluminum cladding sheet will not. Aluminum jacket will only produce oxidation. Therefore, in some thermal insulation projects, thermal insulation aluminum jacketing sheet is more cost-effective than iron jacket sheet, because it has a high cost performance, so we must pay attention to this point when purchasing aluminum sheet. The antirust property of 3003 aluminum cladding roll is higher than that of 1060 aluminum jacketing roll. The alloy of 3003 aluminum has extremely high Mn element (compared with 1000 series), accounting for about 1%. This is also why the rust resistance of 3003 aluminum jacket is higher than that of 1060 aluminum jacket. Of course, the price of 3003 aluminum jacketing is higher than that of 1060 aluminum jacketing.

3, Quality difference of thermal insulation aluminum skin

The performance of aluminum jacketing sheet for ductwork of various aluminium alloys in heat preservation is basically about 3 years, but after roller coating or performance processing, it can be improved to about 20 years.

live:onlinehcx