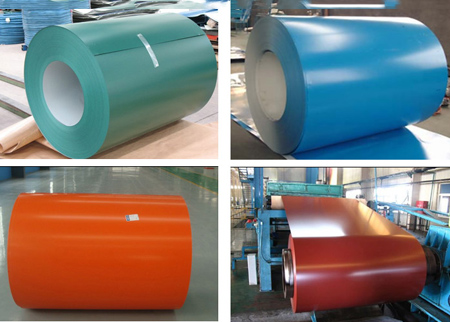

Color coated aluminium coil is frequently used for their good combination of strength and form-ability anodizing behavior weld-ability and corrosion resistance.

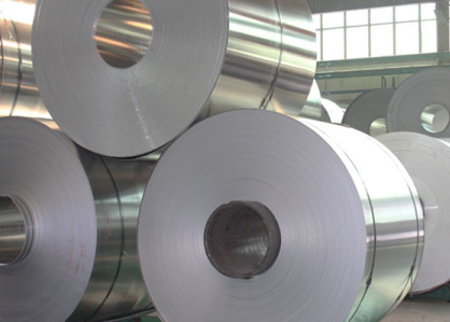

1100 aluminum coil is soft and has low strength, so it is not suitable for high-strength, high-pressure or hardness applications.

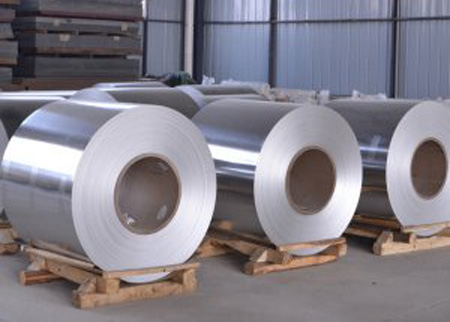

5754 aluminum coil of different heat treatments are the main materials of manufacturing automotive industry (such as car door, mold, seal components), and the canning industry.

Haomei can manufacture 5083 aluminum coil with many tempers, such as O, H32, H34, H112, H116, H321, etc., and it can be cut to size at customers’ need.

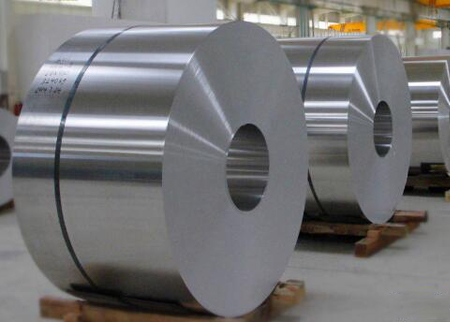

5052 aluminum coilof Haomei Alu is certificated to ASTM B209 and it can be cut to size at customers’ need. The main content is Mg.

Properties of 3003 Aluminum Coil 3003 aluminum alloy is an aluminium-manganese alloy which approximately 20% stronger than alloy 1100.

1050 aluminum coil belongs to commercially pure wrought family with a purity of 99.5% Aluminum.

6061 aluminum coil is one of the most popular aluminum coil alloys. It comprises magnesium and silicon as primary alloying elements.

1060 aluminum sheet is pretty similar to 1050 aluminum alloy with more than 0.1% of aluminum by weight.

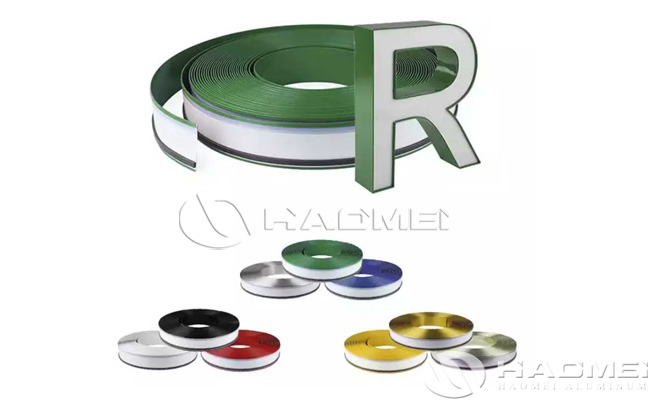

Aluminum channel letter coil is a type of material commonly used in the signage industry to create channel letters.

Product Lists

Breif Introduction of Us

Haomei Aluminum

live:onlinehcx