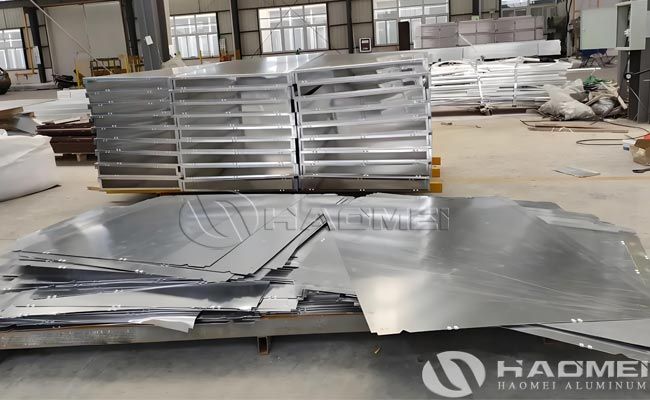

Aluminum sheet for sign making is a widely used material for advertising, indication and decoration. Aluminum signs are usually formed by stamping, cutting, dimpling and die-casting aluminum alloy, and the common processes include high-gloss (polished), rot-engraved, oxidized, brushed, laser engraving, electroplating, spraying, spot-painting, enameling, baking, reflective, and glow-in-the-dark printing, etc. The color of the surface content is screen printed, four-color offset printing, and thermal transfer printing to complete the color effect. Surface content color using screen printing, four-color offset printing, thermal transfer printing to complete the color effect, can be printed with a variety of text, number, pattern and other content.

Commonly used type of aluminum sheet for sign making are:

1. 1000 Series Pure Aluminum Sheet (such as 1060, 1100)

- Characteristics: Aluminum content of more than 99%, with excellent ductility, conductivity and corrosion resistance, but lower strength, suitable for scenes that do not require high strength.

- Applications: general signage, billboards, interior decoration, etc.

2. 3000 Series Aluminum-Manganese Alloy Sheet (e.g. 3003, 3004)

- Characteristics: added manganese element, strong anti-rust performance, higher strength than 1000 series, while maintaining good molding and welding properties.

- Applications: outdoor signage, traffic signage, architectural decoration, etc.

3. 5000 Series Aluminum-Magnesium Alloy Sheet (e.g. 5052, 5083)

- Characteristics: Containing magnesium elements, it has higher strength, corrosion resistance and low temperature resistance, suitable for complex environments.

- Applications: ships, automobile signboards and highly demanding outdoor signs.

4. Other Alloy Aluminum Sheets (e.g. 6061, 6063)

Characteristics: Containing magnesium and silicon elements, medium strength, suitable for surface oxidation treatment, commonly used in high-end decorative signs.

The reason why aluminum sheet is suitable for signage production:

1. Corrosion resistance

Aluminum sheet surface is easy to form an oxide film, natural resistance to rust and corrosion, suitable for long-term outdoor use.

2. Light weight and easy processing

The low density of aluminum makes it easy to transport and install; it can be flexibly shaped by cutting, stamping, welding and other processes.

3. Surface treatment diversity

Supports spraying, anodizing, laminating and other processes to meet the needs of different visual effects (e.g. reflective, matte).

4. Cost-effective

1000 series pure aluminum sheet has lower cost and is suitable for mass production; alloy aluminum plate strikes a balance between strength and cost.

Application scene of aluminum signs are:

- Outdoor signage: anodized aluminum sheet with reflective film are required to ensure weather resistance and all-weather visibility;

- Equipment nameplates/furniture signs: black anodized aluminum is recommended to enhance texture and brand recognition;

- Industrial safety signage: the substrate needs to be paired with a high temperature resistant, fade-proof process and an eye-catching warning color scheme.

Regarding the quality requirements, the quality standards of aluminum signage include but are not limited to the following aspects:

- Material selection: high-quality aluminum should be selected in line with national or industry standards, such as GB/T3880-2006 specified in the different thickness specifications of the aluminum plate.

- Surface treatment: It is necessary to ensure that the surface of the signage is flat and smooth, without scratches, creases or breaks, and can be painted, oxidized and colored or other decorative treatment according to actual needs.

- Durability and stability: considering the possibility of outdoor use, aluminum signage must have excellent weather resistance and long-term exposure to harsh environments without deformation.

To sum up, aluminum sheet is the ideal material for sign making not only because of its superior physical and chemical properties, but also because it can adapt to different design and technical requirements, while ensuring the quality and service life of the final product.

live:onlinehcx